In the IMAGE project airframe noise is addressed by tackling both landing gear and high-lift devices, through basic configuration mock-up, which are the two main contributors to airframe noise of an aircraft at approach. Engine noise is addressed through its fan components, which account for a large fraction of the engine contribution to far-field noise. Installation effects on jet noise are addressed for a turbofan engines mounted underneath the wing.

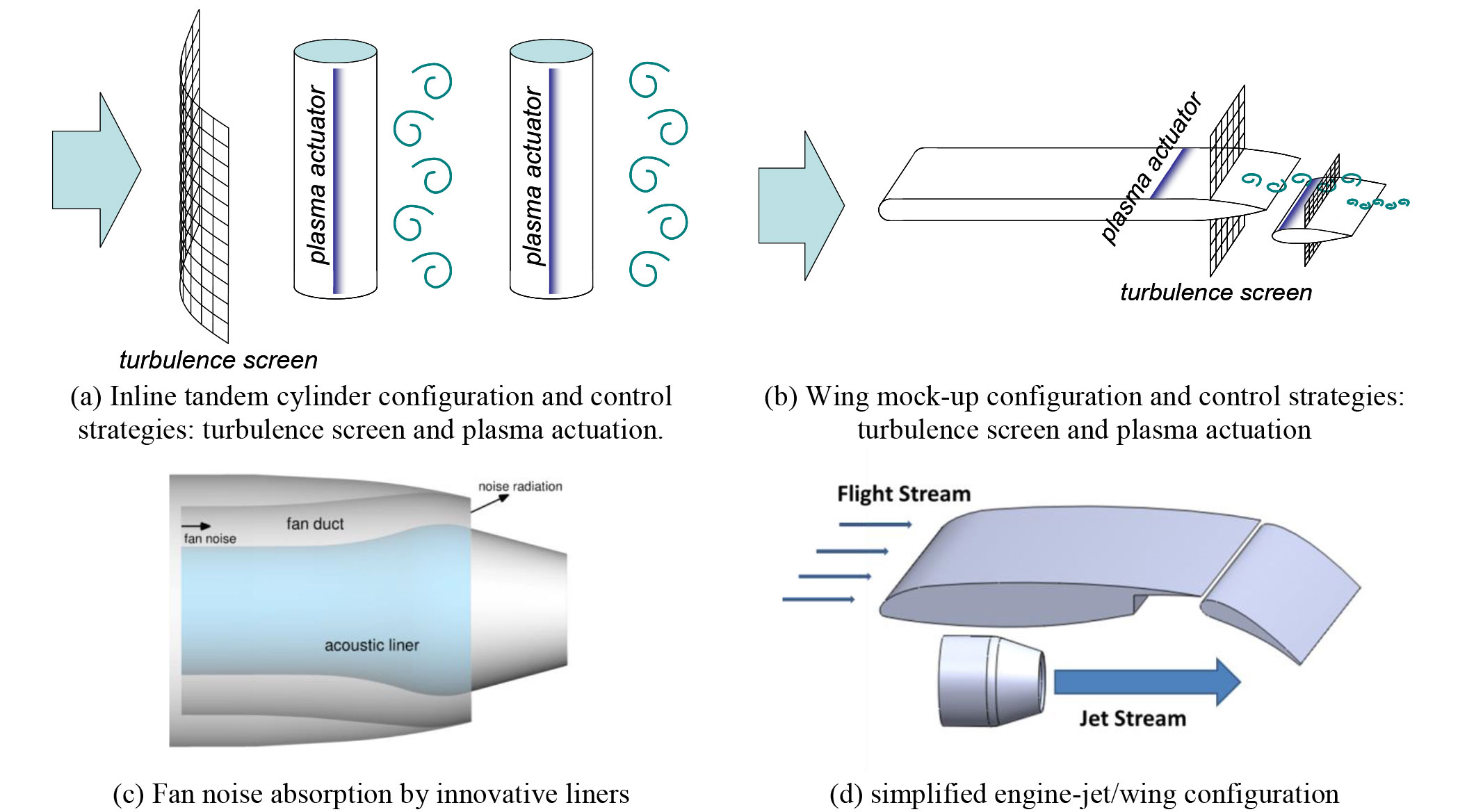

As already mentioned in Section 1.1, the IMAGE project targets a few most promising active and passive control strategies for comprehensive studies, focusing on plasma actuation, turbulence screens (meshes) and innovative porous materials (acoustic liners). These noise-control technologies will be addressed in the framework of three basic flow configurations: tandem cylinders, simplified wing mock-up and engine-fan duct, as the representative in respective association to landing-gear noise, high-lift noise and engine noise. Installation effects will be assessed for a fourth basic flow configuration: simplified engine-jet/wing configuration.

A fundamental study in the framework of these basic flow configurations provides a consolidate basis for: (1) understanding the noise generation mechanism since each of these basic flow configurations represents the main HL or LG flow features associated inherently to the most potent aerodynamic noise generation, and consequently, (2) understanding comprehensively of the control mechanism and supporting further improvement of these control strategies aiming at supressing potent contributors to aircraft noise. These flows are generic with no ambiguity of the flow physics in experimental measurements and numerical analysis for robust tackling of various noise control methods.

The wing mock-up and tandem cylinders are quite complementary, and permit to investigate the performance of the different control approaches on streamlined and bluff bodies, respectively. It is indeed lack of a full understanding at present time, how control techniques such as plasma actuation or turbulence screens behave in relation to the strength of the flow separation and resulting vortex motions. The type of control and amount of energy required to stabilize the pressure-driven mild separation of the boundary layer past a streamlined airfoil may be significantly different in the case of a massive separation past a bluff body. Comparing the experimental results in both cases will help to elucidate questions as such.

By means of experimental and numerical studies for the three selected noise-reduction technologies applied to the three aforementioned basic configurations as well as for the selected baseline configuration for installation effects, IMAGE will

- Generate and/or document (if already existing) an accurate experimental database of the baseline configurations (not being subjected to noise control), focused on the aerodynamic flow features in relation to noise generation.

- Generate a new, detailed and accurate experimental database on the physics of the three noise reduction technologies;

- Further improve acoustic measurement methods with a particular focus on the beamforming technology;

- Improve experimental techniques to determine the acoustic properties of novel acoustic liner designs and increase the understanding of the effect of realistic operating conditions;

- Develop, validate, and evaluate numerical modelling methods for the effect of each flow-induced noise source actuation and/or acoustic reduction method;

- Undertake comprehensive CFD/CAA analysis of noise generation, propagation and control measures and, further, validate and improve CAA and hybrid CFD/analogy tools;

- Conduct aero-acoustic optimization of these noise-control devices and further improve the optimization tools for industrial use in low-noise designs;

- Document the numerical methodologies, assess the noise-reduction technologies, and provide guidelines for potential industrial use in problem diagnosis and in low-noise designs.

- Explore the acoustic installation effect for an engine-jet/wing configurations;

On the basis of the studies with the basic flow configurations, IMAGE will

- Evaluate the effectiveness of selected control approaches for realistic airframe configurations;

- Make a technical assessment and scaling towards potential industrial.

A rational choice of the most suitable control strategy is significantly complicated in the absence of any quantitative experimental or numerical assessment of different control approaches. This crucial need is fulfilled by new reference experimental data and systematic comparative studies of different control strategies as applied to generic configurations reflecting the physics of noise-generation by the noisiest elements of civil aircraft. That systematic work will

- contribute to documentation of the pros and cons of different control approaches and

- form a trusty experimental database for elaborating physically consistent numerical models.

An important part of IMAGE will be the characterization and modelling of innovative porous materials and liner layouts for the reduction of fan noise, including the effects of mean flow and non-linear effects caused by high sound intensity, over a broad frequency range. Although the works devoted to the impedance of materials including flow effects have been conducted since the 1970s, the mechanisms underlying the acoustic response of the medium in the presence of flow have not yet been fully examined. Furthermore, recent manufacturing techniques permit producing new layouts and structures, giving increased and extended absorption characteristics with zero weight penalty and minimal manufacturing complexity. New porous materials can also be arranged in locations that were not considered before (e.g. over the surface of the OGVs). Additionally, the effective impedance of fan noise by acoustic liners becomes more difficult for future propulsion concepts such as the ultra-high bypass ratio turbofan as a result of fan tones shifting to lower frequencies, relative shortening of the intake and exhaust ducts, and possible non-uniformity of the inlet and exhaust flows.

The fundamental mechanism through which turbulence screens damp out the noise generation and propagation process is so far subjected to wide conjectures. This mechanism will be further investigated in IMAGE by means of experiments and from a numerical modelling viewpoint. It was shown in the EU TIMPAN project that the noise emitted by a simplified landing gear can be considerably reduced by placing perforated fairings upstream of the landing gear, but noise reduction has also been observed with turbulence screens located downstream of the considered obstacle. Turbulence screens may modify the flow around the airframe in two different ways: either through the mean flow and thus the global levels of generated noise or through the turbulent structures which directly drives the frequency content of the generated noise. Moreover, the turbulence screens may have a filtering/damping action on the acoustic waves generated by the interaction of the flow and the airframe. Consequently, modelling these technologies in the CFD/CAA solvers requires detailed experimental characterization, with aerodynamic and acoustic effects possibly decoupled: mean/unsteady flow modifications can be measured in a small closed section wind tunnel, whereas acoustic filtering can be approached without flow in an anechoic room. In relation to the above investigation, IMAGE will also make an effort to evaluate any possible aerodynamic penalties (e.g., increased drag) for optimal use of turbulence screens in actuating noise generation and propagation.

In parallel to the two aforementioned passive control approaches, active control with a proper actuator and a suitable control strategy can be a promising alternative. Particularly, the plasma-based actuator has gained increasing investigation in flow separation control for drag reduction but has received much less attention for noise control. The plasma actuators can be entirely surface mounted with no mechanical parts, and possess high bandwidth while requiring relatively low power, allowing simple, light, low cost, robust and reliable control systems to be realised. The simplicity and absence of any mechanical moving parts offers unprecedented possibilities for airframe noise control. In IMAGE we will explore new control strategies to devise efficient airframe noise control systems with plasma actuators of different types on the basis of the recent PLASMAERO project (ERCOFTAC Workshop, 2012).

A fundamental point of interest is the development of simplified, yet reliable, representations of the effects of control devices in a CFD context. Because of the intrinsic cost of the unsteady CFD simulations that are involved in CAA and hybrid approaches, having a simplified, macroscopic description of the control device is required in order to simulate the steady and transient behaviour of the controlled flow in an affordable way. This is a pre-requisite to the optimization and, eventually, implementation of the control techniques in the application field.

To derive modelling and optimization rules for the control methods for improved generality, it is crucial to uncover the intrinsic influence of the actuation alone. One of the main difficulties, however, is to decouple the effect of the flow controller from the main flow features, due to the non-linearity of fluid mechanics. Therefore, a project dealing with a real airframe with slat, flap and landing gear integrated in a realistic complex geometry would not permit to answer the questions concerning the maturity of the control methods. Indeed, such geometry would require out-of-reach computational power and a large scale model tested in very expensive wind tunnels, which are incompatible with the development, systematic comparison and experimental validation of the controller models.

In order to unveil and model the physical mechanisms permitting the control of airframe and fan noise, detailed knowledge will be obtained in IMAGE by studying simplified but representative configurations. For this purpose, three specific basic configurations are selected in IMAGE: tandem cylinders, simplified wing mock-up, and engine-fan duct (Figure 1.3 (a)-(c)).

The tandem-cylinder case is configured with two identical cylinders spatially separated and aligned with the streamwise direction. This configuration has been taken as a test case in the well-respected AIAA/NASA BANC workshops (https://info.aiaa.org/tac/ASG/FDTC/DG/BECAN_files_/BANCII.htm) targeting on benchmarking airframe noise computations in mimicking landing-gear noise generation and emission (D. Lockard et al., AIAA Paper 2007-3450, 2007). This basic configuration possesses the salient flow feature of landing gear in relation to the most potent LG noise generation in the presence of a variety of flow physics and component level interactions in the form of separated shear layers and vortices, which are present in realistic LG configurations. In IMAGE, the well-documented experimental data from the AIAA workshop will be exploited in benchmarking computational methodologies and tools. Making steps forward, noise control technologies, turbulence screen and plasma actuators, will be applied in both experimental and numerical analyses. One of the major targets is to manipulate/control the turbulent flow motions closely associated to noise generation that are very similar to those of a realistic LG configuration. The strategy adopted in IMAGE is to focus on isolated flow physics that are relatively easy to explore and are recognized being the most potent flow-induced noise sources in realistic LG configurations. The outcome of noise control, in terms of the numerical modelling and control technologies using turbulence screen and plasma actuators, is highly relevant to addressing realistic LG noise generation, control and reduction. Indeed, these basic configuration represent the main flow features that are the most potent “noise generators” in realistic configurations and applications. The mechanism of the control approaches is first investigated in relation to noise generation and propagation on these basic configurations representing airframe and fan applications. The control strategies are then further improved in aero-acoustic optimization. The tandem cylinders are representative of landing gears, the simplified wing mock-up is a representation of a wing with deployed high-lift device, and the engine-fan duct accounts for the engine fan noise. Making one-step forward, the IMAGE project will also address the installation effects on an enginejet/ wing configuration, as shown in Figure 1.3(d). This case has been simplified from an engine-under-wing configuration, which is a common installation of modern commercial aircraft. For ultra-high-bypass-ratio modern turbofans, the engine would be installed much closer to the wing, leading to increasing jet/wing interaction, particularly when the high-lift devices are deployed during aircraft landing or take-off. In relation to this, three technical aspects will be addressed in IMAGE: (i) aeroacoustic interaction in relation to the turbulent flows over the engine jet/wing installation; (ii) scattering effects of the wing on the jet noise; (iii) potential guidelines on designs for low-noise jet/wing installation. (a) Inline tandem cylinder configuration and control strategies: turbulence screen and plasma actuation. (b) Wing mock-up configuration and control strategies: turbulence screen and plasma actuation. (c) Fan noise absorption by innovative liners (d) simplified engine-jet/wing configuration

Figure 1.3: (a)-(c) Generic airframe and engine noise configurations considered in IMAGE; (d) A simplified engine-jet/wing configuration exploring installation effects in IMAGE.

The investigation will be conducted using advanced experimental technologies and numerical methods. These methodologies will undergo further development and improvement to drive the best achievements from the project work. The noise-reduction strategies will be improved by means of aeroacoustic optimization. An overall evaluation and assessment of the investigated control strategies will also be undertaken led by industrial partners.